Can-bus emulation for cruise control

Introduction

This is intended as a reference for those who would like to emulate the can-bus messages for the cruise control.

Application: Any swapped vehicles that do not have can-bus support. It would cover both the Bosch ME7.1.1 and a ME17.5/ME17.5.6

Hardware required

You can use any microcontroller that have CAN-bus capability, such as an Arduino or ESP32. You could also use the SpeedPulser Pro that already has a GPS and CAN-bus capability, you would only need to alter the source code and implement the new CAN-bus message:

- https://forbes-automotive.com/products/speedpulser-pro

- https://github.com/adamforbes92/speedPulserPro

CAN-bus: What is this sorcery?

CAN-bus is a network used by modules to transmit data/information with each other. With only two wires, you can transmit a multitude of messages between modules (multiplexing).

In the past, you would have a single wire for every input. In those instances, every button of your cruise control switch has its own signal wire.

The objective of the CAN-bus emulation is to take all those signals, feed them into your microcontroller and output CAN-bus messages that the ECU will understand, as if it was on a factory MK5/MK6 2.5 chassis.

CAN-bus messages required:

- State of the cruise control switch (Ex.: Main switch, SET, RES, etc.), normally provided by the steering column module

- Vehicle speed, normally provided by the ABS module

Vehicle speed acquisition

The vehicle speed can be retrieved through the following means:

- GPS module

- VSS sensor

- Hall-effect sensor mounted into the instrument cluster to read the speed of the speedometer cable

- There are more ways to gather this information depending on your creativity

Emulating the cruise control switch

The ECU receive the cruise control switch information through the CAN message 0x38A. Here is a detailed description of this CAN message

| Signal | Byte | Start bit | Bits | Range / Values | Notes |

|---|---|---|---|---|---|

| Checksum (See below) | 1 | 0 | 8 | 0..255 (Phys = Hex) | — |

| Main switch | 2 | 0 | 1 | 0 = OFF 1 = ON |

Latching ON/OFF |

| Tip switch OFF | 2 | 1 | 1 | 0 = not pressed 1 = pressed |

— |

| Tip switch DECEL | 2 | 2 | 1 | 0 = not pressed 1 = pressed |

— |

| Tip switch ACCEL | 2 | 3 | 1 | 0 = not pressed 1 = pressed |

— |

| Cruise decelerate (hold) | 2 | 4 | 1 | 0 = not decelerating 1 = decelerating |

— |

| Cruise accelerate (hold) | 2 | 5 | 1 | 0 = not accelerating 1 = accelerating |

— |

| Cruise control stalk error | 2 | 6 | 1 | 0 = OK 1 = stalk error |

— |

| Not used | 2 | 7 | 1 | — | — |

| Tip switch SET | 3 | 0 | 1 | 0 = not pressed 1 = pressed |

— |

| Tip switch RESUME | 3 | 1 | 1 | 0 = not pressed 1 = pressed |

— |

| Sender coding | 3 | 2 | 2 | 00 = Body network 01 = Steering column module 10 = Engine |

Values per spec |

| Message counter | 3 | 4 | 4 | 0..15 (Phys = Hex) | Rolling counter |

| Not used | 4 | 0 | 8 | — | Byte 4 unused |

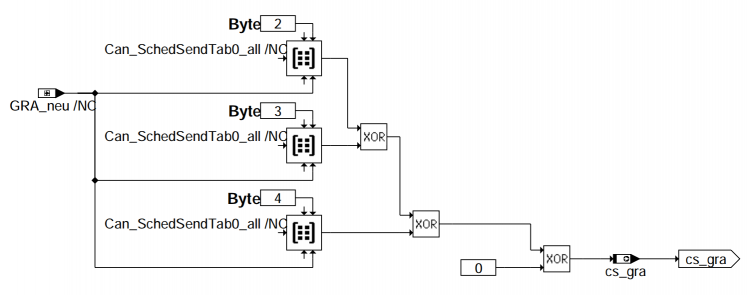

Checksum

The checksum is a formula used to validate the integrity of the message, and detect possible data corruption during the transmission of the message. If the checksum does not match the data, the ECU might reject the message. (Implausible message)

This checksum is calculated only with Exclusive OR (XOR) operations

Code example

This is a very rough sketch to show a possible implementation. This example would be for an Arduino controller using a MCP2515 shield (hat).

// demo: Cruise control switch, analog to can-bus message for VW PQ35

// Very rough sketch, but should work. Feel free to improve

#include <SPI.h>

#define CAN_2515

// Set SPI CS Pin according to your hardware

#if defined(SEEED_WIO_TERMINAL) && defined(CAN_2518FD)

const int SPI_CS_PIN = BCM8;

const int CAN_INT_PIN = BCM25;

#else

// For Arduino MCP2515 Hat:

// the cs pin of the version after v1.1 is default to D9

// v0.9b and v1.0 is default D10

const int SPI_CS_PIN = 9;

const int CAN_INT_PIN = 2;

#endif

#ifdef CAN_2518FD

#include "mcp2518fd_can.h"

mcp2518fd CAN(SPI_CS_PIN); // Set CS pin

#endif

#ifdef CAN_2515

#include "mcp2515_can.h"

mcp2515_can CAN(SPI_CS_PIN); // Set CS pin

#endif

const int buttonMain = 4;

const int buttonRes = 2;

const int buttonSet = 0;

byte oldSwitchState = 0x0;

byte sequence = 0x0;

void setup() {

SERIAL_PORT_MONITOR.begin(115200);

while(!Serial){};

while (CAN_OK != CAN.begin(CAN_500KBPS)) { // init powertrain can bus : baudrate = 500k

SERIAL_PORT_MONITOR.println("CAN init fail, retry...");

delay(100);

}

SERIAL_PORT_MONITOR.println("CAN init ok!");

pinMode(buttonMain, INPUT_PULLUP);

pinMode(buttonRes, INPUT_PULLUP);

pinMode(buttonSet, INPUT_PULLUP); // default state 12v

}

void loop() {

byte switchState = 0x0;

// Read analog inputs

int stateMain = digitalRead(buttonMain);

int stateRes = digitalRead(buttonRes);

int stateSet = digitalRead(buttonSet);

// You can more inputs and adjust the logic according the the can-bus chart

if (stateMain == LOW) {

switchState |= (1 << 0); // Set bit 0

}

if (stateSet == LOW) {

switchState |= (1 << 1); // Set bit 1

}

if (stateRes == LOW) {

switchState |= (1 << 2); // Set bit 2

}

// Check if the switch state has changed

if (switchState != oldSwitchState) {

Serial.println(switchState); // Print new state for monitoring purposes

oldSwitchState = switchState; // Update oldSwitchState

}

// Define bytes for can message (0x38A)

byte byteTwo = switchState & 1;

byte byteThree = switchState >> 1;

byteThree = byteThree | 0xC; // Could also be 0x4 (See Sender coding)

byteThree = (sequence << 4) | byteThree;

byte checksum = byteTwo ^ byteThree;

unsigned char payload[4] = {checksum, byteTwo, byteThree, 0x00};

CAN.sendMsgBuf(0x38A, 0, 4, payload);

sequence = (sequence + 1) & 0x0F; // increment for the next frame

delay(20); // Send every 20ms

}